Views: 199 Author: Site Editor Publish Time: 2025-06-27 Origin: Site

In recent years, environmental concerns have become increasingly important in the world of marine sports. The impact of fuel consumption, emissions, and material waste has pushed designers and manufacturers to seek more sustainable solutions. One key focus is on creating racing boats that are not only fast and competitive but also eco-friendly.

Lightweight and efficient materials play a crucial role in achieving this balance. By reducing the overall weight of a boat, less energy is needed to propel it, which directly lowers fuel consumption and emissions. This improves both performance and environmental impact.

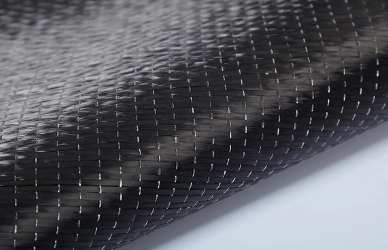

Carbon fiber fabric has emerged as a leading material in this pursuit. Known for its exceptional strength-to-weight ratio, corrosion resistance, and durability, carbon fiber fabric offers a sustainable choice for racing boat construction. Its use helps produce lighter, stronger boats that perform better while reducing their environmental footprint.

The weight of a racing boat directly influences its speed and efficiency on the water. Heavier boats require more power to achieve high speeds, which in turn increases fuel consumption. This not only raises operating costs but also contributes to higher carbon emissions. In competitive racing, where every second counts, a lighter boat can accelerate faster and maintain higher speeds with less energy, giving racers a significant advantage.

By using lightweight materials like carbon fiber fabric, boat manufacturers can significantly reduce the overall weight without compromising structural strength. Lighter boats demand less fuel, resulting in lower emissions and a smaller environmental footprint. Additionally, enhanced agility and responsiveness improve handling and safety, making the boat more efficient both in performance and sustainability.

Traditional boat-building materials such as fiberglass, aluminum, and wood tend to be heavier or less durable compared to carbon fiber fabric. Fiberglass, while cost-effective, adds considerable weight and can be prone to fatigue over time. Aluminum offers strength but is heavier and less flexible in design. Wood, though lightweight, requires extensive maintenance and lacks the durability needed for high-performance racing. Carbon fiber fabric outperforms these materials by combining lightness, strength, corrosion resistance, and design versatility, making it the preferred choice for eco-friendly racing boats.

Carbon fiber fabric provides outstanding strength while being extremely lightweight. This unique combination makes it perfect for building racing boats that require both high strength and speed without adding unnecessary weight. Its excellent strength-to-weight ratio helps improve overall boat performance, allowing for faster acceleration and better handling on the water.

Exposed to saltwater and humid conditions, racing boats require materials that resist corrosion. Carbon fiber fabric excels in this, offering excellent protection against water damage and reducing maintenance needs.

The fabric’s flexibility allows it to be molded into complex, aerodynamic shapes. This capability enables designers to create efficient boat parts that improve speed and handling.

Racing boats face tough environments and repeated stress. Carbon fiber fabric is highly durable and resistant to fatigue, ensuring long-lasting performance under demanding marine conditions.

Manufacturing racing boats with carbon fiber fabric involves laying multiple fabric layers and impregnating them with resin through methods like vacuum bagging or resin transfer molding (RTM). This creates lightweight, strong composite structures that closely fit the mold shapes.

Carbon fiber fabric is used in hull panels for strength and impact resistance, in masts for improved sail performance, and in rudders and decks to reduce weight and enhance durability—boosting boat speed and control.

Using carbon fiber fabric improves structural strength and stiffness while allowing designers to create complex shapes and aerodynamic profiles. This flexibility leads to better weight distribution and higher performance in racing boats.

One of the primary environmental advantages of using carbon fiber fabric in racing boats is the significant reduction in overall weight. A lighter boat requires less engine power to reach high speeds, which directly lowers fuel consumption. Reduced fuel usage means fewer greenhouse gas emissions, contributing to a cleaner marine environment and helping to combat climate change.

Carbon fiber fabric is highly durable and resistant to corrosion and fatigue, which extends the service life of racing boats. This longevity means fewer boats need to be replaced over time, reducing material waste and the environmental impact associated with manufacturing and disposal processes.

While recycling carbon fiber composites is still developing, advances in recycling technology hold promise for the future. Efforts to recover and reuse carbon fibers from old composites can minimize waste and reduce the demand for virgin raw materials. This potential enhances the sustainability of carbon fiber racing boats as environmental concerns continue to grow.

Many leading racing teams and boat manufacturers have embraced carbon fiber fabric for its unmatched combination of strength and lightness. Companies specializing in high-performance marine vessels increasingly choose carbon fiber to build hulls, masts, and other key components, aiming to gain a competitive edge in speed and agility.

The adoption of carbon fiber fabric has led to noticeable performance gains, such as faster acceleration, higher top speeds, and better handling in challenging conditions. Alongside these improvements, many teams highlight the environmental benefits, including reduced fuel consumption and lower emissions, aligning their racing goals with sustainability.

Notable success stories abound, from championship-winning sailing yachts that use carbon fiber sails and hulls to motorized racing boats that rely on carbon fiber components for lightweight strength. These examples showcase how carbon fiber fabric not only boosts performance but also supports eco-friendly innovation in competitive marine sports.

Carbon fiber fabric plays a vital role in the development of racing boats that combine high performance with eco-friendly benefits. Its exceptional lightweight strength and durability allow boats to reach higher speeds while consuming less fuel, which significantly reduces environmental impact. This balance of speed, efficiency, and sustainability is increasingly important as the marine industry moves toward greener technologies and stricter environmental regulations worldwide.

For companies and engineers seeking reliable, high-quality carbon fiber fabric, QingNiao Carbon Fiber Materials Co., Ltd. stands out as a trusted and experienced supplier. The company specializes in producing carbon fiber fabrics that are not only of excellent quality but also stable and consistent, meeting the rigorous demands of racing boat manufacturing. Partnering with QingNiao ensures that designers and builders have access to materials that support both superior performance and environmental responsibility, helping to drive ongoing innovation in eco-friendly marine solutions and sustainable sportsmanship.