A Reliable Composites Manufacturer

Jiaxing Qingniao is a private enterprise specializing in carbon fiber and its composite materials, which are extensively used across industries including aerospace, automotive, and sports equipment. The company consistently adheres to a market demand-oriented approach, driven by technological innovation, and is committed to building an industrial ecosystem centered around carbon fiber technology.

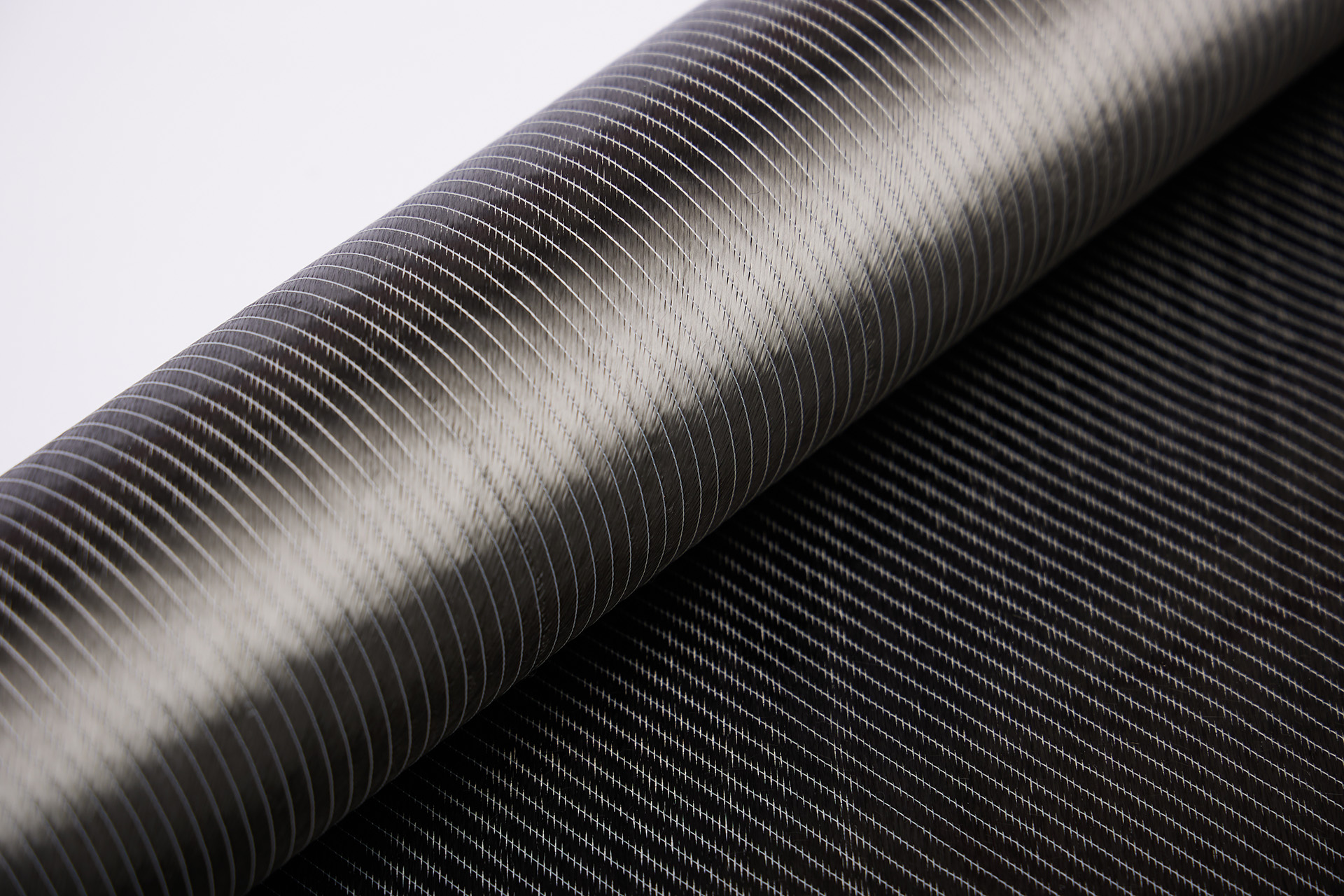

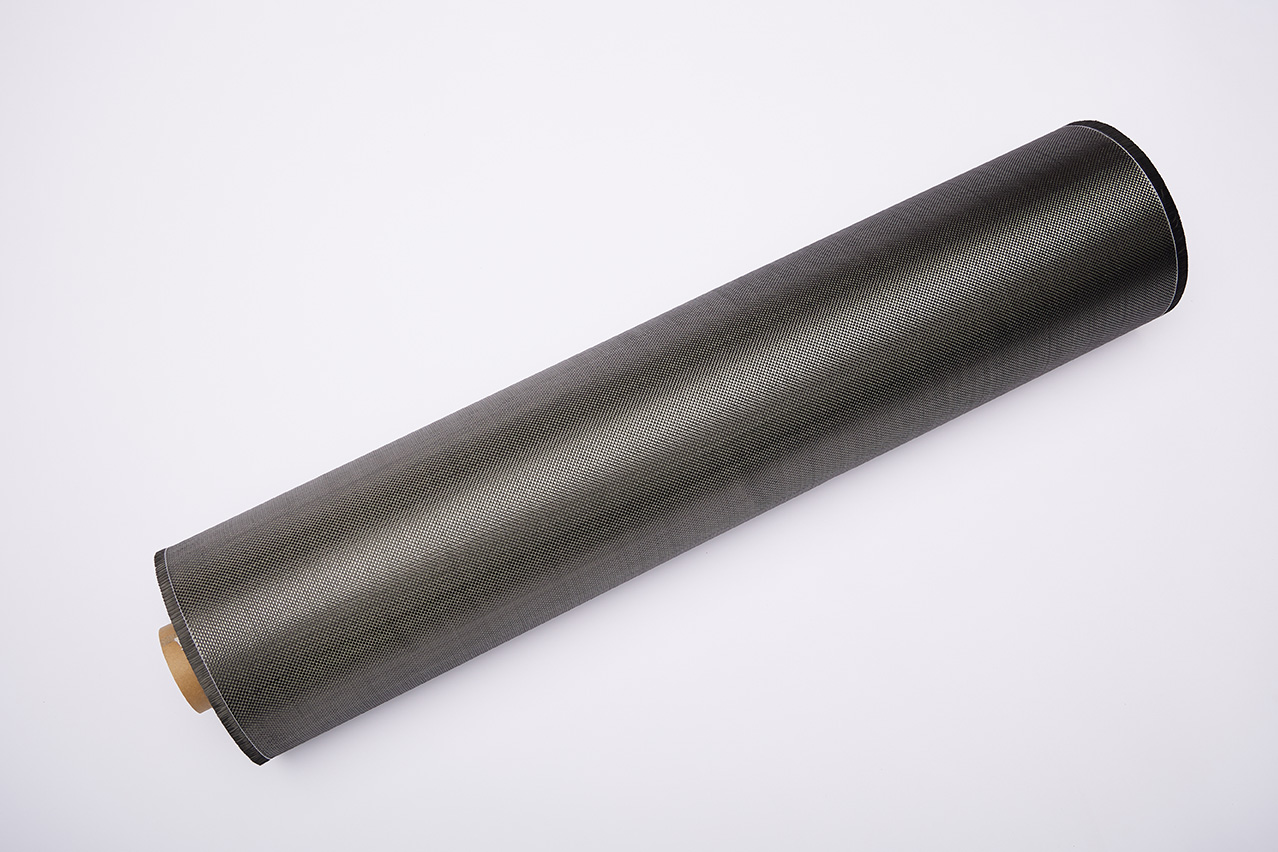

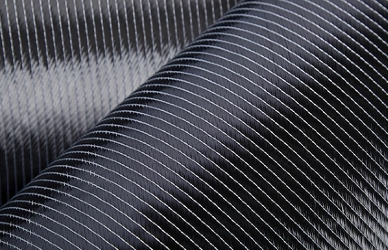

Carbon fiber fabric is a two-dimensional or three-dimensional textile produced by weaving continuous carbon fiber filaments through plain, twill, or unidirectional weaving processes. As the core substrate for manufacturing carbon fiber reinforced polymers (CFRP), it features a monofilament diameter of merely 5-10 micrometers and a carbon content exceeding 90%, combining exceptional properties including high strength (3,000-7,000 MPa), lightweight design (density 1.6-2.0 g/cm³), and superior corrosion resistance. It is one of the key reinforcing materials for manufacturing high-performance composite materials.

Company Services

We are a leading manufacturer of carbon fiber, mainly producing carbon fiber fabric, carbon fiber products, pickleball rackets and other products. The company provides customized services to meet your needs. Samples can be sent free of charge, and the shipping cost is negotiable.

Additionally, carbon fiber fabric exhibits dual conductivity—electrical conductivity three times greater than steel—allowing simultaneous integration of lightweight design and electromagnetic shielding capabilities. This multifunctional material bridges advanced engineering requirements with sustainable innovation.

Weaving Method: (1)Plain Weave; (2)Twill Weave; (3)Satin Weave; (4)UD Fabric

Brand: QINI

Width/ Weight: Support Customization

Fabrication Processes

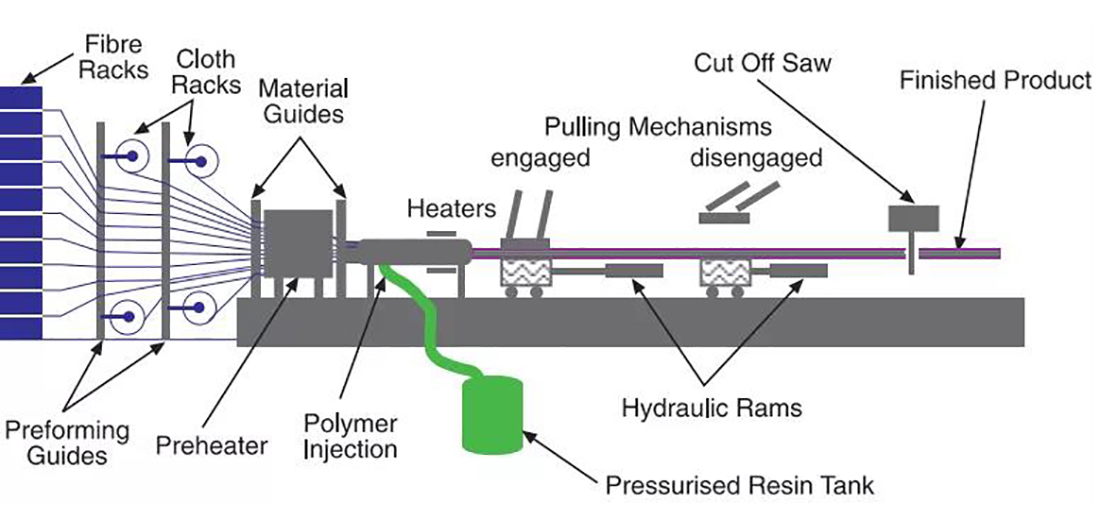

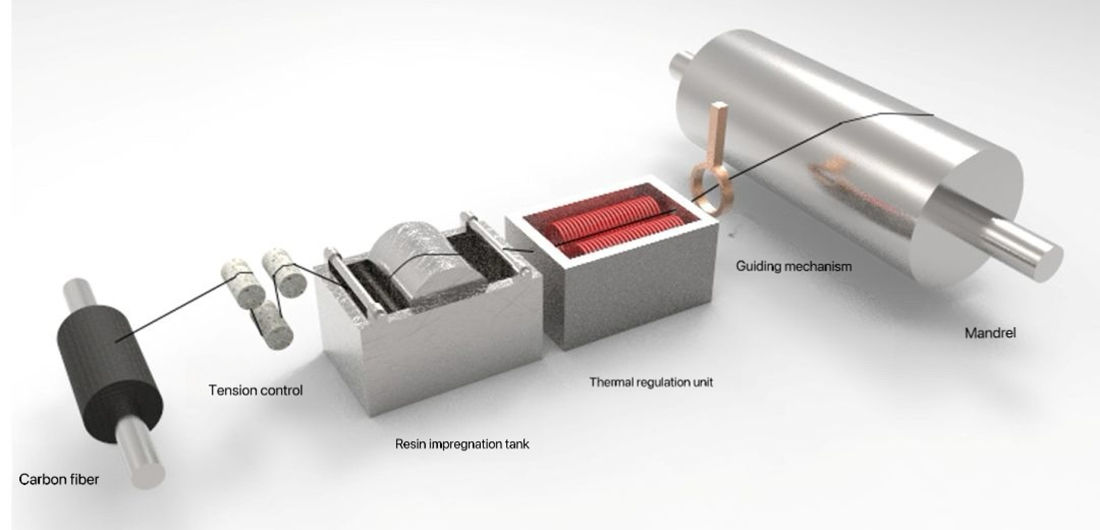

Pultrusion Process

It is suitable for manufacturing low-cost composite materials with high fiber volume content. The process includes impregnating the continuous fiber with resin under the action of traction equipment, heating it through the molding die, squeezing out the excess resin, and solidifying it. This process can be continuously formed, the length of the product is not limited, the longitudinal mechanical properties are outstanding, the production process is highly automated, the production efficiency is high, the product performance is stable, and the cost is low.

Winding Process

The winding process is often used to manufacture products such as pressure vessels, fishing rods, transmission shafts, and is also widely used in the field of civil engineering. The process includes winding the continuous fiber soaked in resin glue onto the core mold according to a certain pattern, and then curing and demolding to obtain the product. The fiber made by the winding process can maintain continuity and integrity, the product has high strength, can be mechanized and continuously produced, and has a short production cycle.

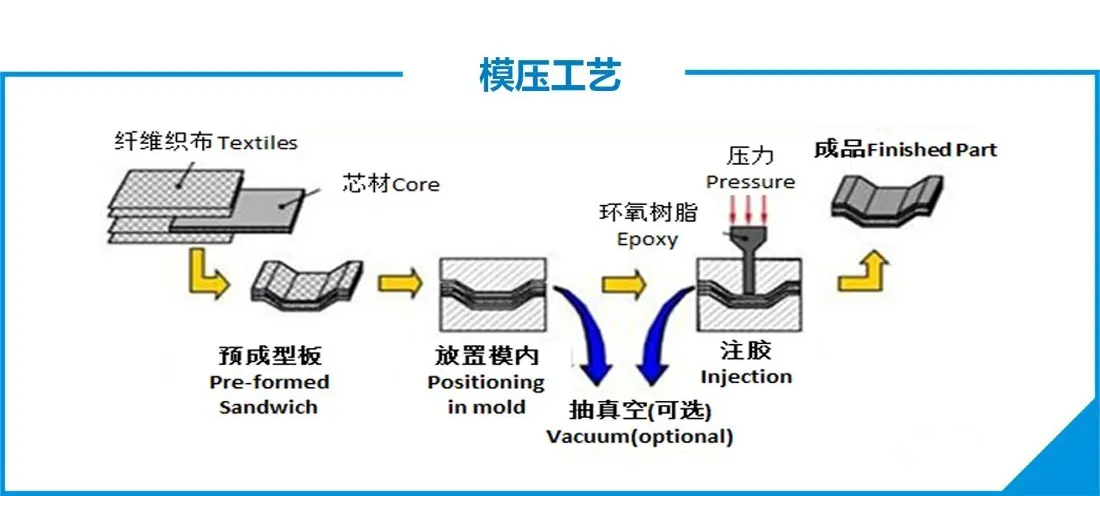

Molding Process

Carbon fiber compression molding is an efficient process that solidifies carbon fiber prepreg or chopped fibers with a resin matrix by heating and pressurizing. It is suitable for the production of high-precision, high-strength composite parts and is widely used in aerospace, lightweight automobiles, and other fields. The main advantages of compression molding are high production efficiency, easy to achieve specialized and automated production, high product dimensional accuracy, good repeatability, etc., and can be mass-produced.

Application

Sporting Equipment

Fishing rods, golf clubs, bicycles, rackets, ski poles, etc. in our daily life are all made of carbon fiber, which can better ensure the usability of the items.

Automotive Field

Carbon fiber materials due to its high strength, lightweight, and corrosion resistance can be used to replace steel in cars, reducing the overall weight of the car.

Wind Power Generation

Its lightweight and high-strength characteristics significantly improve the power generation efficiency and reliability of wind turbines.

FAQs

How to maintain carbon fiber products?

(1) Avoid impact with sharp objects.

(2) Use neutral solvents when cleaning, and do not scratch with hard objects.

(3) Long-term exposure to ultraviolet rays requires a protective coating.

How to place an order or request a quote?

Visit our website and contact our customer service team for assistance.(www.qinicf.com)

Can carbon fiber fabric be folded?

No, carbon fiber fabric cannot be folded. While it exhibits exceptional tensile strength, its shear resistance is comparatively weaker, making it prone to fiber fracture when subjected to bending or folding stresses.

How high a temperature can carbon fiber fabric withstand?

Carbon fiber fabric is divided into unidirectional and bidirectional types. The carbon fiber fabric itself can withstand high temperatures up to 1000°C. However, carbon fiber fabric requires adhesive bonding, and the adhesives used for carbon fiber fabric typically can only endure temperatures up to 65°C.

Related Blogs

-

Carbon fiber fabric has become increasingly popular in the automotive industry due to its exceptional strength, lightweight properties, and sleek appearance. It is widely used in various automotive parts, from exterior components like hoods and spoilers to interior trims and structural reinforcements.

Carbon fiber fabric has become increasingly popular in the automotive industry due to its exceptional strength, lightweight properties, and sleek appearance. It is widely used in various automotive parts, from exterior components like hoods and spoilers to interior trims and structural reinforcements. -

Carbon fiber materials have become increasingly prevalent across a wide range of industries, from aerospace and automotive to sports equipment and medical devices. Known for their exceptional strength-to-weight ratio and durability, carbon fiber composites are revolutionizing how products are designed and manufactured.

Carbon fiber materials have become increasingly prevalent across a wide range of industries, from aerospace and automotive to sports equipment and medical devices. Known for their exceptional strength-to-weight ratio and durability, carbon fiber composites are revolutionizing how products are designed and manufactured.