| Availability: | |

|---|---|

Description

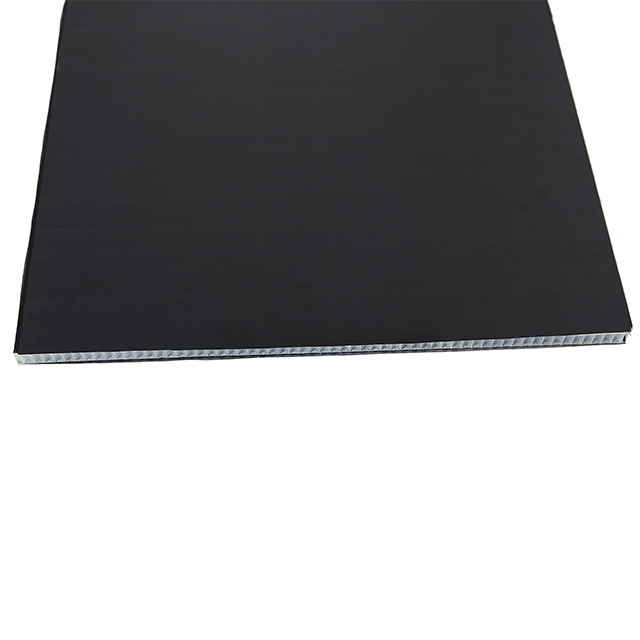

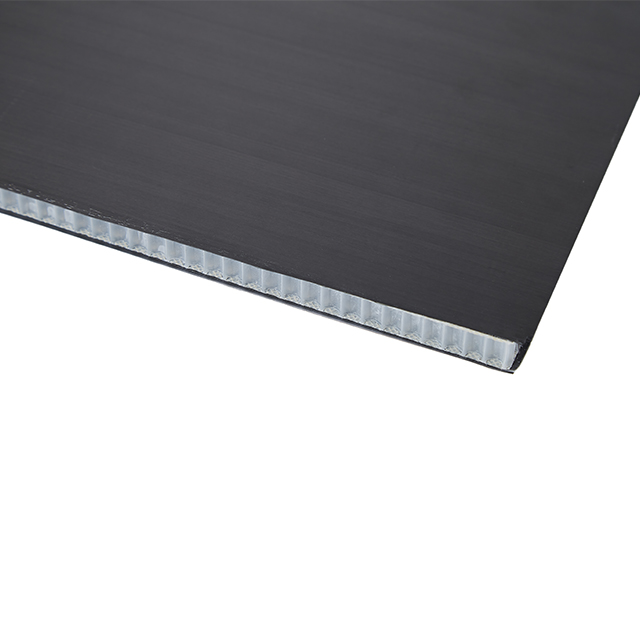

QINI PP Honeycomb Carbon Fiber Board is a high-performance composite panel engineered to address the core pain points of traditional carbon fiber composite panels: high manufacturing costs and weak impact resistance. Composed of a PP honeycomb sandwich core and double-sided carbon fiber layers, this innovative panel combines the tensile strength of carbon fiber with the lightweight structure of PP honeycomb, making it a top choice for B2B clients in high-demand industries. As a professional carbon fiber composite manufacturer, QINI strictly controls every production process to ensure the panel’s structural stability and performance consistency, meeting the rigorous standards of global customers.

Parameter | Specification |

Maximum Size | 9000*3000mm |

Minimum Thickness | >0.2mm |

Core Material Options | PP honeycomb, aluminum honeycomb, aramid honeycomb |

Surface Material | High-quality carbon fiber |

Brand | QINI |

Process Caracteristics

The manufacturing process of QINI PP Honeycomb Carbon Fiber Board is a testament to advanced composite technology. First, high-performance adhesives are used to bond carbon fiber layers to both sides of the honeycomb core, ensuring tight integration between each layer. The assembled panel is then heated and pressurized to cure, a step that enhances interlayer adhesion and structural rigidity. This meticulous process eliminates common defects such as delamination and warping, guaranteeing a reliable and long-lasting product.

Application Area

| >> AerospaceUsed to manufacture structural parts and interior components of aircraft, rockets, and satellites. The panel’s lightweight design reduces overall vehicle weight, improving fuel efficiency and launch payload capacity. |

>> AutomobileApplied in car bodies, bumpers, and interior trims. By replacing traditional metal parts, the panel cuts vehicle weight by up to 30%, boosting fuel economy and collision safety. |

|

| >> Sports EquipmentIdeal for producing high-performance bicycles, skis, and surfboards. The panel’s strength and durability enhance equipment performance while keeping it lightweight for athletes. |

>> ConstructionServes as sound insulation, thermal insulation, and decorative materials. The panel’s corrosion resistance and insulation properties make it suitable for both indoor and outdoor building projects. |

|

Advantages

The integration of carbon fiber layers and PP honeycomb core delivers an exceptional strength-to-weight ratio, supporting heavy loads without adding excess weight. This feature is critical for applications where weight reduction is a priority, such as aircraft structural parts and automotive body components.

The hollow hexagonal structure of the PP honeycomb core traps air, creating a natural barrier against sound and heat transfer. Paired with the thermal stability of carbon fiber, the panel is ideal for building insulation materials and vehicle interior parts that require acoustic and thermal control.

Made with chemically stable PP material, the honeycomb core resists erosion from acids, alkalis, and other harsh chemicals. This durability ensures the panel maintains its performance even in corrosive environments, reducing long-term maintenance costs for clients.

The panel can be cut, drilled, bent, and molded to fit diverse project requirements. Whether clients need large-size panels for construction or precision components for sports equipment, QINI can adjust dimensions and core materials to match specific needs.