Views: 0 Author: Site Editor Publish Time: 2025-08-05 Origin: Site

The choice between Kevlar and carbon fiber depends on five big things: strength, weight, durability, flexibility, and cost. Both materials are used a lot in industries that need things to be light and strong. In 2023, their total market value was about USD 3.5 billion. This shows fast growth in aerospace, defense, and car industries. Each factor can change how well the material works. People should think about what they need, like protection, sports, or car parts, when they compare these materials.

Kevlar is very good at taking hits and bending. It does not break easily. This makes it great for safety gear and protection.

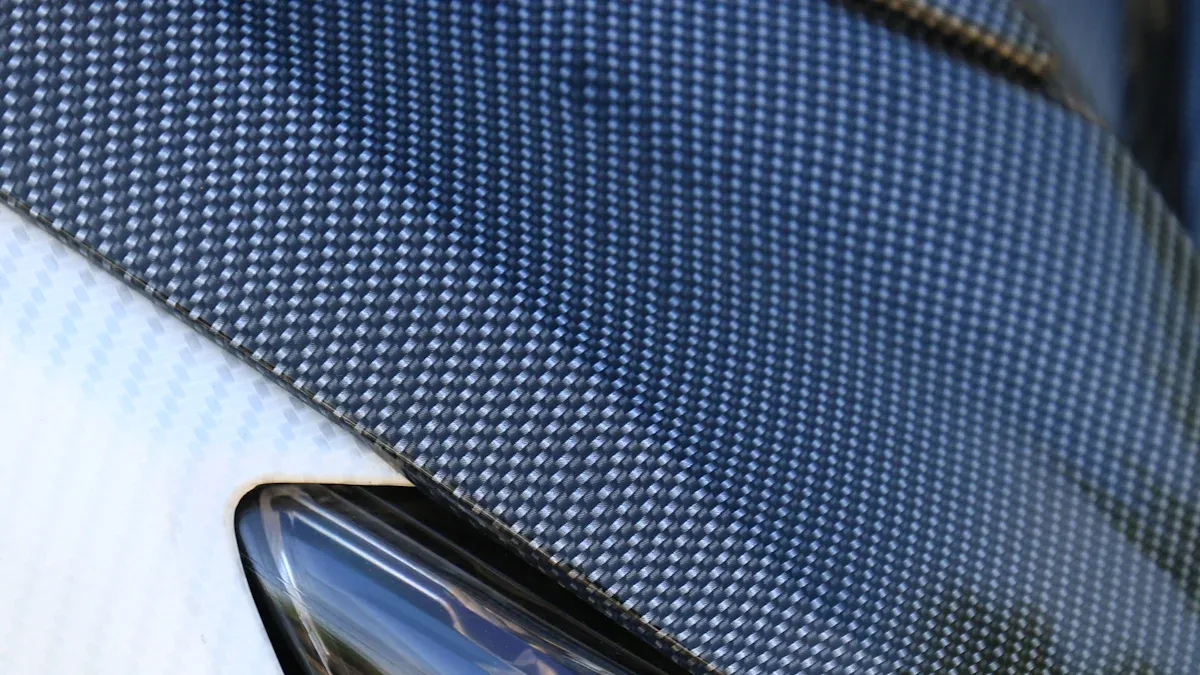

Carbon fiber is stronger and stiffer than Kevlar. It is good for making light but strong things. People use it for car frames and airplane wings.

Kevlar weighs less than carbon fiber. This helps save fuel. It also makes safety gear easier to wear.

Kevlar can handle many hits and heat well. Carbon fiber is harder but can break more easily. It is still very strong for stiff things.

Kevlar is cheaper and works well for protection. Carbon fiber costs more but lasts a long time. This can save money later.

Kevlar is very strong and tough. It has a tensile strength of about 3,620 MPa (525,000 psi). This number is important in material science. Kevlar fibers can stretch and take in energy. This helps them stop fast objects. That is why Kevlar is used in body armor and safety gear. Kevlar is strong for its weight. It can handle hard hits. This keeps people safe in risky places.

A closer look at different Kevlar types shows how it works:

| Kevlar Type | Tensile Modulus (GPa) | Relative Density (g/cm³) | Tensile Strength (GPa) | Extension to Break (%) |

|---|---|---|---|---|

| Kevlar 29 | ~71 | ~1.43 | ~2.8 | ~4.5 |

| Kevlar 49 | ~134 | ~1.46 | ~2.8 | ~2.9 |

| Kevlar 129 | ~98 | ~1.46 | ~3.5 | ~3.2 |

| Kevlar 149 | ~144 | ~1.48 | ~2.4 | ~1.6 |

These numbers show why Kevlar is good for stopping impacts.

Carbon fiber is also known for being strong and stiff. Studies say carbon fiber often has more tensile strength than Kevlar. How strong it is depends on how it is made and tested. Most times, carbon fiber is stronger than Kevlar for building things. Carbon fiber is also good at handling pressure. This makes it great for making light but strong parts. It is used in planes, cars, and buildings. Carbon fiber does not bend or stretch much under heavy loads. This helps it work well in tough places.

Kevlar and carbon fiber are both strong in their own ways. Carbon fiber usually has more tensile and compressive strength. This makes it better for things that need to stay stiff and strong. Engineers pick carbon fiber for airplane wings, car frames, and sports gear. These things need to handle stress over and over. Kevlar is best when you need to stop impacts or absorb energy. It is used in body armor and safety panels. In short, carbon fiber is stronger for building things. Kevlar is better for stopping hits and sudden forces.

Kevlar is known for being very light. Its density is about 1.44 to 1.45 g/cm³. This makes Kevlar lighter than many other materials. Engineers pick Kevlar when they want less weight but still need strength. Kevlar has a high strength-to-weight ratio. That is why it is used in aerospace, cars, and defense. For example, airplane panels and bulletproof vests use Kevlar. These things stay light but still protect people.

Kevlar is light, so cars and planes use less fuel. It also makes safety gear easier to wear.

| Fiber Type | Density (g/cm³) | Key Practical Implications |

|---|---|---|

| Kevlar | 1.44 | Used in composites and protective gear where low weight is critical |

Carbon fiber is a bit heavier than Kevlar. Its density is about 1.8 g/cm³. But it is still much lighter than metals like steel or aluminum. Carbon fiber is strong and stiff for its weight. Designers use carbon fiber for parts that must be light and hard. In planes and cars, carbon fiber can cut weight by up to 40%. This helps cars go faster and planes use less fuel. Carbon fiber is also used in sports gear like tennis rackets and bikes. Light gear helps athletes play better.

| Fiber Type | Density (g/cm³) | Key Practical Implications |

|---|---|---|

| Carbon Fiber | 1.8 | Suitable for lightweight, high-performance composites |

Kevlar weighs less than carbon fiber. Both are much lighter than metals. Kevlar’s lower density is good when every gram matters. Kevlar is picked for gear and parts that must take hits. Carbon fiber is a little heavier but is stiffer and stronger. This makes it great for building strong parts.

Industries where lightweight materials matter most include:

Aerospace: Airplane wings, bodies, and blades

Automotive: Sports cars, brakes, and strong tires

Defense & Security: Bulletproof vests and helmets

Sporting Goods: Tennis rackets, bikes, and helmets

Marine: Boat bodies and sails

Renewable Energy: Windmill blades

Medical: Fake limbs and braces

Kevlar’s low density makes it best for light, impact-resistant things. Carbon fiber’s strength and stiffness are good for projects that need to be strong and last long.

Kevlar is known for being tough and lasting a long time. It can take many hits without breaking. Tests show Kevlar soaks up energy and does not get damaged easily. Kevlar fibers bend instead of breaking apart. This helps stop big failures. Kevlar stays strong in most weather and places. It can handle heat up to 350°F (177°C). Water does not make Kevlar much weaker. Most regular chemicals and salt do not hurt Kevlar. Only strong acids or bases at high heat can damage it, but this is rare in daily life. Kevlar can take stress over and over better than many other things. Even when used a lot, Kevlar keeps its shape and strength for years. Thick Kevlar does not get hurt by sunlight much. Thin Kevlar fabric can lose strength if left in the sun for a long time.

Kevlar is good for safety gear because it breaks in a way you can expect and soaks up energy.

Carbon fiber is very strong and stiff, but it does not handle hits as well. If carbon fiber breaks, it loses its strength fast. Carbon fiber is great for parts that need to be stiff. But it is more likely to snap than Kevlar. If you hit carbon fiber in the same spot many times, it gets damaged more than Kevlar does. Some things mix carbon fiber and Kevlar together. These mixed materials can take hits better and stay strong after damage. Special tests, like listening for sounds or using heat cameras, help find damage inside carbon fiber. These tests make sure the material is still safe after stress or tough use.

Kevlar and carbon fiber both last a long time, but they act differently. Kevlar can take many hits and bends instead of snapping. Carbon fiber is stiffer and stronger, but it can break suddenly after damage. When you mix Kevlar and carbon fiber, the material can take more hits and stay strong. People pick Kevlar when they need something tough that can take hits. Carbon fiber is picked for things that must be very stiff and strong. The best choice depends on what you need it for.

| Property/Aspect | Kevlar | Carbon Fiber |

|---|---|---|

| Impact Resistance | Very high | Moderate |

| Damage Tolerance | Excellent | Lower |

| Performance in Heat | Up to 350°F (177°C) | Good |

| Moisture Resistance | Limited absorption | Good |

| Failure Mode | Bends, predictable | Brittle, catastrophic |

Kevlar can bend and take in energy well. Its molecules make it both strong and bendy. When something hits Kevlar, the fibers stretch instead of breaking. This helps Kevlar take hits and go back to normal. Sports gear makers use Kevlar in things like tennis racket strings and paddles. It is also used in safety gear. These items must handle many hits and shocks. Kevlar is good for ropes and cables too. Here, being bendy and tough is very important. In building, Kevlar layers make materials tougher. This helps stop cracks and breaks.

Kevlar is picked when you need to stop hits and soak up energy.

Carbon fiber is very stiff and strong. It does not bend much before it breaks. This makes it great for parts that must keep their shape. Engineers use carbon fiber in airplane wings and car frames. It is also used in wind turbine blades. These things must stay firm and not bend. But carbon fiber can snap if pushed too far. In sports, carbon fiber rackets and bike frames are powerful and precise. They do not feel as soft as gear made with Kevlar.

| Property / Fiber Type | Kevlar Fiber | Carbon Fiber | Hybrid Composites (Kevlar + Carbon + Glass) |

|---|---|---|---|

| Strain to Failure | High strain capacity, flexible | Low strain capacity, brittle | Improved strain before fracture due to Kevlar layers |

| Flexural Strength | Moderate | Maximum flexural strength | Highest flexural strength when carbon fiber layers are optimized |

| Flexural Modulus | Lower modulus | High modulus | Highest modulus in certain stacking sequences |

| Impact Strength | High impact strength, absorbs energy | Lowest impact strength, brittle | Synergistic effect improves impact strength beyond Kevlar alone |

| Failure Mode | Deforms significantly, tough | Catastrophic brittle failure | Kevlar layers bridge cracks, prevent brittle failure |

Kevlar and carbon fiber are good for different things. Kevlar is bendy and tough. It is best for safety gear, ropes, and sports gear that must take hits. Carbon fiber is stiff and strong. It is best for building parts in planes, cars, and wind turbines. Sometimes, both fibers are mixed together. These mixes give both shock absorption and strength.

| Application Area | Kevlar (Flexible) | Carbon Fiber (Stiff) |

|---|---|---|

| Sports Gear | Body armor, paddles, racket strings | Bike frames, tennis rackets |

| Structural Uses | Ropes, cables, impact panels | Car frames, airplane wings |

Mixing Kevlar and carbon fiber lets designers choose how bendy or stiff they want the material to be.

Kevlar is not too expensive and is useful. Many companies use Kevlar because it protects well and costs less. The price of Kevlar depends on how thick the sheets are and how heavy the fabric is. How the Kevlar is made also changes the price. If the fabric is lighter, you need more layers, so it can cost more. The resin type matters too. Epoxy resin costs more money. Polyester and vinyl ester resins are cheaper. Kevlar is picked for safety gear, car parts, and sports gear. It works well and does not cost too much.

Carbon fiber costs more than Kevlar. Making carbon fiber is hard and uses lots of energy. The main material, called PAN, is pricey and needs many steps like heating and stretching. Factories must follow strict rules, especially for plane and car parts. These steps make carbon fiber cost more. Some products mix carbon fiber and Kevlar. These mixes can cost even more but are better at taking hits. The price also changes if the sheets are thicker, the fabric is heavier, or the way it is made is different.

The main things that change the price for both are:

How thick and how many layers the sheets have

How heavy and what kind of fabric is used

How the product is made (wet layup, vacuum infusion, hot press)

What kind of resin is used

What is happening in the market and new technology

Kevlar is a better deal for many things, like safety gear and parts that need to take hits. It is lighter and bends more, so it is great for safety stuff. Carbon fiber is stronger and stiffer. It is picked when you need strong and light parts, like in cars and planes. Carbon fiber costs more at first, but it can save money later because it lasts longer and does not need much fixing.

| Aspect | Kevlar Composite | Carbon Fiber Composite |

|---|---|---|

| Initial Cost | Lower | Higher |

| Maintenance | Not detailed | Lower |

| Lifespan | Good | Very long |

| Value for Protection | High | Moderate |

| Value for Structure | Moderate | High |

Kevlar is great for safety gear. Its fibers soak up energy and stop impacts. This makes it good for body armor, helmets, and safety panels. People pick Kevlar to protect against sharp things or hard hits. Kevlar bends instead of snapping, so it helps stop injuries. Sports and military gear often use Kevlar to keep people safe in crashes. Some products mix Kevlar and carbon fiber. These mixes give even better protection. They use Kevlar’s toughness and carbon fiber’s strength. This helps them soak up more energy and stop impacts better.

Tip: For the best safety, pick things with Kevlar layers or mixes in spots that get hit a lot.

Carbon fiber is best for building strong things. Engineers use it for airplane wings, car frames, and racing bikes. It is stiff and keeps its shape under heavy weight. Carbon fiber does not stretch much. It works well when you need parts that are light and strong. Sometimes, Kevlar and carbon fiber are mixed together. These mixes are strong and can bend a bit without breaking. They soak up more energy and do not crack as easily as just carbon fiber. How you mix the fibers changes how tough and bendy the part is.

| Material Type | Strength | Toughness | Best Use Cases |

|---|---|---|---|

| Kevlar | High | Very High | Protective gear, impact panels |

| Carbon Fiber | Very High | Moderate | Structural parts, race cars |

| Hybrid Composite | Balanced | High | Aerospace, advanced structures |

Kevlar is a good choice if you want to save money. It costs less than carbon fiber but still works well. Kevlar is used in cheaper and mid-level products. People who want strong and light parts for less money pick Kevlar for rally cars and off-road vehicles. Carbon fiber costs more and is used in fancy products. It is picked for top racing cars because it is very stiff and lasts a long time. Mixing Kevlar and carbon fiber can save money and make parts tougher. These mixes are smart for projects that need both safety and strength.

Note: If you want to spend less, Kevlar and mixes give good results without the high price of pure carbon fiber.

Kevlar is great at stopping impacts and can bend without breaking. It also stays strong in heat. This makes Kevlar good for safety gear and things that need to soak up energy. Carbon fiber is very stiff and strong when pulled. It is also light, so it works well for building parts that must be strong but not heavy. If you want the best protection, pick Kevlar. If you need parts that are super light and stiff, use carbon fiber. When both are mixed, you get a material that is strong and tough for special uses.

Tip: Think about what matters most for your project—strength, weight, durability, flexibility, or cost.

To learn more about picking materials, check guides from experts and companies.

Kevlar can bend and take hits well. Carbon fiber is very stiff and strong. Kevlar is best for safety and protection. Carbon fiber is best for making strong parts.

Engineers sometimes mix Kevlar and carbon fiber. This makes a material that is tough and strong. These mixes are used in planes, sports gear, and cars.

Carbon fiber makes bikes and rackets light and stiff. Kevlar helps them last longer and take hits. Many sports brands use both to make better gear.

Carbon fiber costs more than Kevlar most of the time. Making carbon fiber takes more energy and time. Kevlar gives good protection for less money.