Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

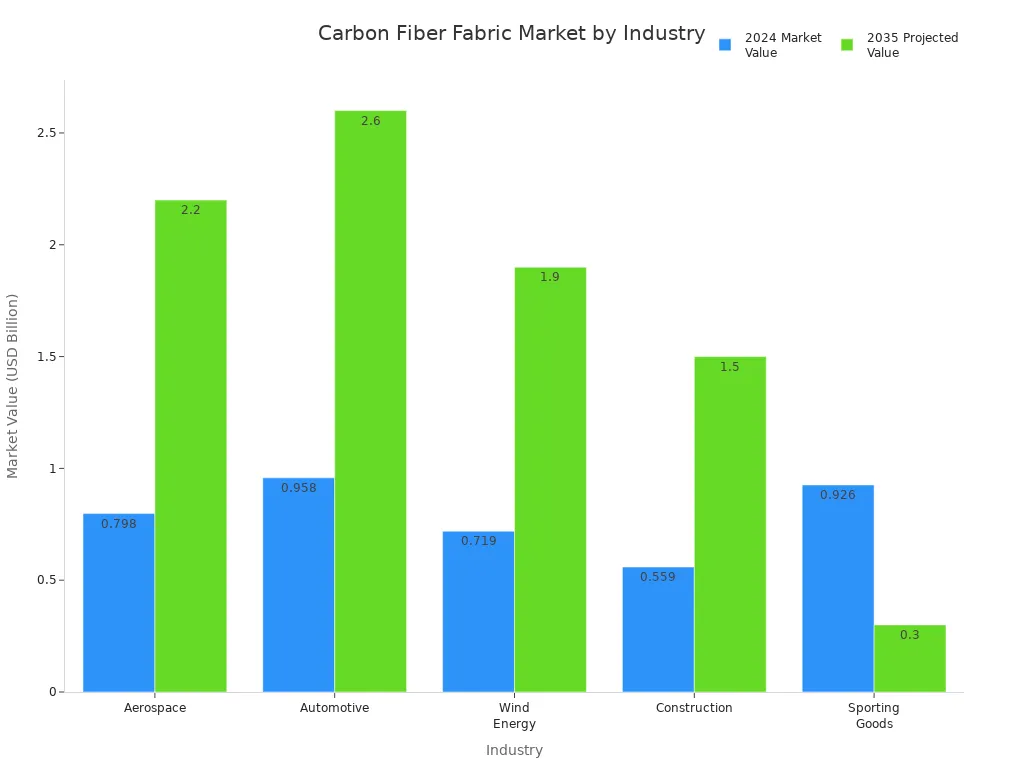

Carbon fiber fabric is now very important in many industries. It is strong and light. This helps engineers make safer airplanes, faster cars, and stronger buildings. In the last ten years, more people want carbon fiber fabric. It is used a lot in aerospace, automotive, and construction. The fabric is much stronger for its weight than old materials. Reports say that car makers use more carbon fiber fabric every year. This is because of electric cars and new car designs.

Carbon fiber fabric is now very important in many industries. It is strong and light. This helps engineers make safer airplanes, faster cars, and stronger buildings. In the last ten years, more people want carbon fiber fabric. It is used a lot in aerospace, automotive, and construction. The fabric is much stronger for its weight than old materials. Reports say that car makers use more carbon fiber fabric every year. This is because of electric cars and new car designs.

| Metric/Category | Value/Statistic |

|---|---|

| Global Market Size (2024) | USD 1.95 Billion |

| Aerospace Market Share (2024) | ~35% of total market volume |

| Automotive Market Share (2024) | 26% of total fabric utilization |

| Construction Market Share (2024) | >12%, driven by structural rehabilitation and earthquake-resistant buildings |

Carbon fiber fabric is very strong and light. It helps make products safer and faster. It also makes them last longer. Many industries use it, like aerospace, automotive, and construction.

It has special properties. It is strong for its weight. It can resist heat and chemicals. It lasts a long time. These features help engineers build better and lighter parts.

There are different types of carbon fiber fabric. Some are woven, unidirectional, or non-woven. Each type has its own strengths and flexibility. People use them for many things, like airplanes and sports gear.

Carbon fiber fabric costs more than metals. It is also harder to recycle. But new recycling methods are being made. Better manufacturing is helping too. This makes it more eco-friendly and cheaper.

The future of carbon fiber fabric looks good. More people want it because of green technology. Smarter production is helping as well. It is being used in more fields every year.

Many industries use carbon fiber fabrics in new ways. Aerospace companies make airplanes lighter and stronger with it. This helps planes use less fuel and fly farther. Car makers put carbon fiber fabrics in fancy cars for better safety and speed. These cars can go faster and save gas. Sports equipment makers use carbon fiber fabrics for tennis rackets, golf clubs, and bike frames. These items are light and tough. Drone makers use carbon fiber fabric to build strong frames. Drones can fly longer and carry more things. Marine and industrial companies use these fabrics for parts that do not rust and last a long time.

Note: Carbon fiber fabrics are important in many fields like aerospace, automotive, sports, marine, and construction. Using them makes products work better, last longer, and look new.

| Industry Sector | Significance of Carbon Fiber Fabric |

|---|---|

| Aerospace and Aviation | Makes planes lighter, saves fuel, and keeps people safe |

| Automotive and Motorsports | Helps cars be lighter, faster, and use less energy |

| Sports and Recreation | Makes gear light and strong |

| Marine and Industrial | Gives parts that do not rust and last long |

Carbon fiber fabrics are special because of their strong features. They are very strong but also very light. The fabric is much stronger for its weight than steel or aluminum. This lets engineers use less material and still get strong results. Carbon fiber fabrics do not get damaged by chemicals or heat. They work well in tough places. The fabric does not stretch or change shape much when it gets hot or cold. This is good for parts that must stay the same size. Carbon fiber fabrics last a long time because they do not wear out fast, even when used a lot.

Key properties of carbon fiber fabrics:

Very light but super strong

Stiff and lasts a long time

Does not change shape with heat or cold

Lasts long even with lots of use

These features help industries make products that are lighter, stronger, and more dependable than before.

Carbon fiber fabric is made from very thin fibers. These fibers mostly have carbon in them. The fibers come from two main things: polyacrylonitrile (PAN) and pitch. To make the fibers, companies heat the starting material in special ovens. First, they heat the fibers to about 200–400°C to make them stable. Then, they heat them again to about 1000°C with no oxygen. Sometimes, they heat the fibers even more, up to 3000°C. This makes the fibers stronger and stiffer. After all this, the fibers have more than 92% carbon. PAN-based fibers keep some nitrogen, which helps them bend and stretch. Pitch-based fibers have a very regular shape, so they are stiffer but not as strong.

How the fibers line up and their crystal shape changes how the fabric works. PAN-based fibers are tough and can handle pulling. Pitch-based fibers are stiffer because of their higher modulus. Both types are light and strong. This makes them great for things that need to be strong but not heavy.

| Aspect | PAN-based Carbon Fibers | Pitch-based Carbon Fibers |

|---|---|---|

| Precursor Material | Polyacrylonitrile (PAN) | Petroleum or coal pitch |

| Carbon Content after Carbonization | >90% Carbon, ~5% Nitrogen | High carbon content, often >92% |

| Molecular Structure | Graphitic crystallites with strong covalent bonds along fiber axis | More regular atomic structure, mesophase liquid crystal formation |

| Mechanical Properties | Higher tensile strength, higher compressive strength, lower modulus | Higher modulus, up to 830 GPa |

| Performance Contribution | High strength and toughness | High stiffness, regular structure |

People weave these fibers into different patterns. The most common patterns are plain, twill, and satin. In a plain weave, the fibers go over and under each other. This makes a checkerboard look. Plain weave is very stable but not very bendy. Twill weave has diagonal lines and is both strong and flexible. Satin weave goes over many fibers before going under one. This makes the fabric smooth and easy to wrap around curves.

| Weave Pattern | Description | Characteristics | Typical Applications |

|---|---|---|---|

| Plain Weave | Over/under pattern creating a checkerboard appearance. | High stability, low pliability, harsh crimp causing stress concentrations. | Flat sheets, tubes, simple 2D curves. |

| Twill Weave | Over/under pattern with multiple tows (e.g., 2x2, 4x4) creating diagonal "twill lines." | Moderate stability and formability, fewer crimps than plain weave. | Cosmetic and functional parts with moderate complexity. |

| Harness Satin Weave | Satin weave with varying harnesses (4HS, 5HS, 8HS) passing over multiple tows before under one. | High formability, low stability, smooth appearance. | Complex contours requiring drapability. |

| Spread Tow | Filaments spread out to reduce crimp angle compared to standard tow. | Lower crimp angle, higher strength, smoother surface, easier handling. | Applications needing strength and smooth finish. |

| Uni-Directional | Fibers aligned in one direction without weaving. | Maximum strength in fiber direction, less flexible. | Structural parts requiring directional strength. |

Big companies like Toray, Hexcel, Teijin, and Mitsubishi Chemical make most of the world’s carbon fiber fabric. These companies control about 60–70% of the market. Toray is the biggest because it does a lot of research and makes a lot of fabric. Hexcel and Teijin are also important around the world.

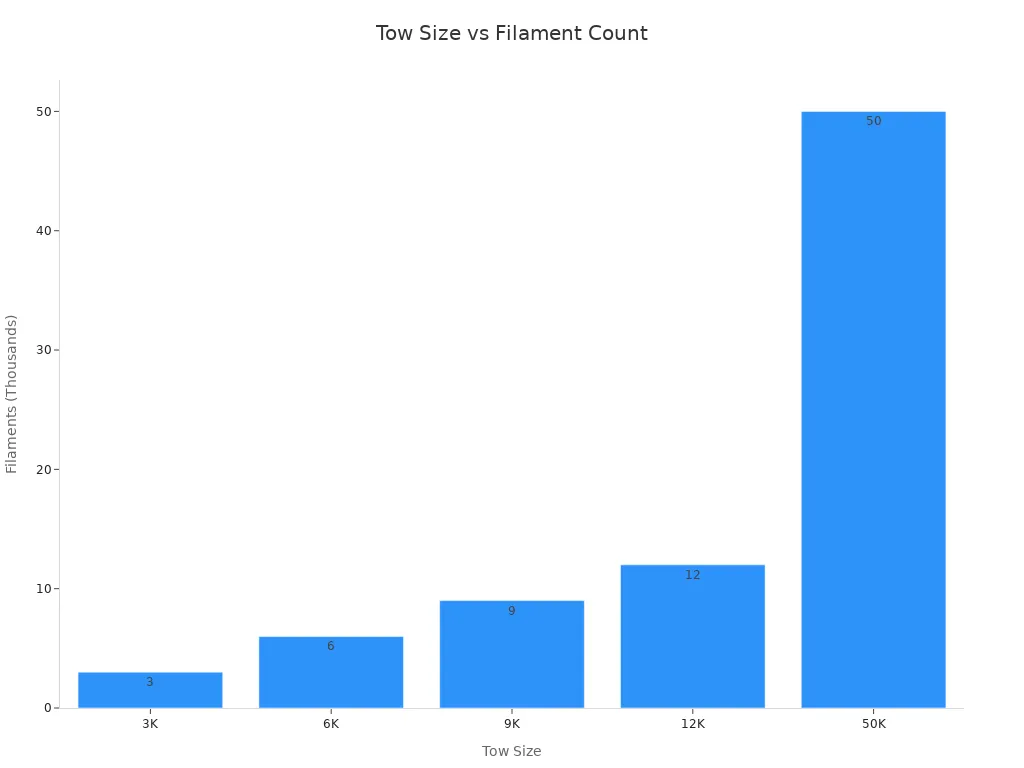

Carbon fiber fabric comes in many types. People can buy it by the yard or in big rolls. For example, a 19.7oz 12K 2x2 twill weave with a 50" width uses a bigger 12K tow size. This kind is not very bendy and is best for flat parts that need to be strong. Lighter 3K tow sizes, sold in 100-yard rolls, are easier to shape and fit around curves. Tow size means how many filaments are bundled together. Smaller tow sizes like 3K are easier to bend, while bigger ones like 12K help build parts faster.

| Form of Carbon Fiber | Description | Tow Size Range | Application Impact |

|---|---|---|---|

| Sold by Yard | Fabric sold in linear yards, e.g., 19.7oz 12K 2x2 twill weave with 50" width | 12K typical | Suitable for fast buildup, heavier tow sizes less drapable, better for flat parts and high strength |

| Sold by Roll | Full rolls, e.g., 5.7oz 3K plain weave fabric in 100-yard rolls | 3K typical | Lighter tow size, more drapable, suitable for structural and cosmetic uses, conforms well to curved surfaces |

| Tow Size | Number of filaments bundled (1K to 24K aerospace-grade; 48K-320K commercial-grade) | 1K-320K | Smaller tow sizes offer better drapability and strength for complex shapes; heavier tows enable faster part build-up, used in industrial, automotive, and recreational markets |

| Aligned Discontinuous Fiber Tows | Specially processed tows with staggered filament ends for improved formability | N/A | More pliable and conformable to curved tooling, enhancing applications requiring complex shapes |

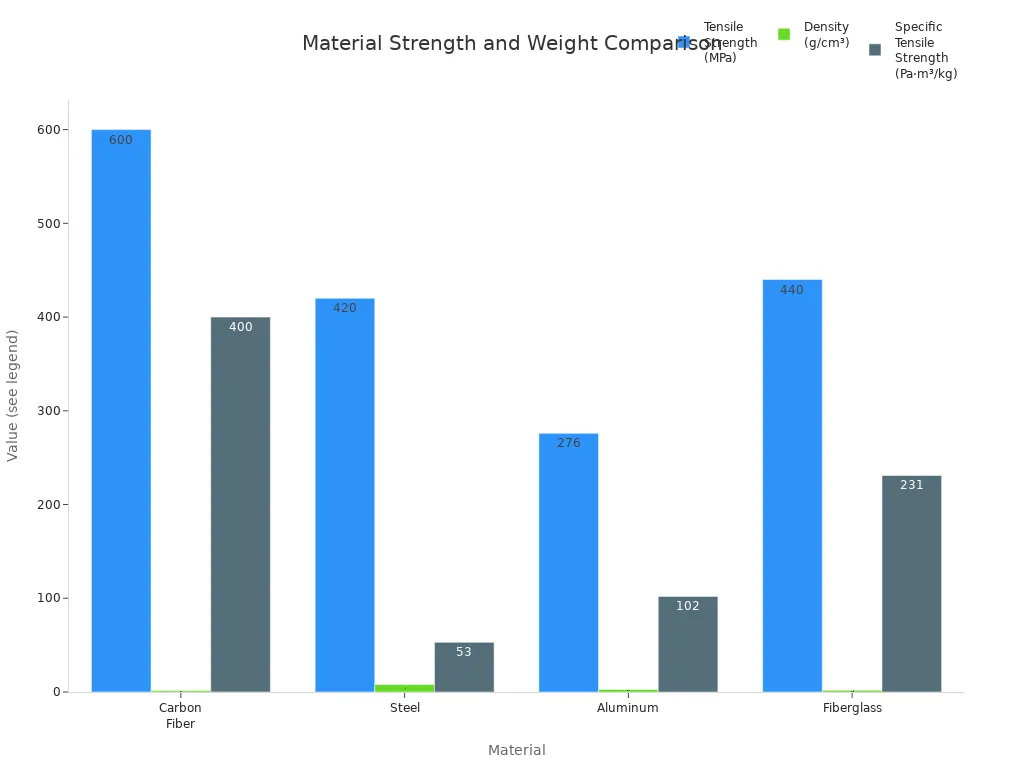

Carbon fiber fabric is much lighter than steel, aluminum, and fiberglass. Its density is about 1.6 g/cm³. Aluminum is about 40% heavier, and steel is even heavier than that. Carbon fiber fabric can handle a lot of pulling, up to 500,000 psi. This is much more than aluminum or steel. Because it is so strong for its weight, it is great for airplanes, cars, and sports gear.

Carbon fiber fabric is about 40% lighter than aluminum.

It is much stronger when pulled than aluminum and steel.

The fabric does not rust and keeps its shape under pressure.

It is stiffer and stronger when pulled but can break more easily than metals.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Specific Tensile Strength (Pa·m³/kg) |

|---|---|---|---|

| Carbon Fiber | ~600 | ~1.5 | ~400 |

| Steel | ~420 | ~7.9 | ~53 |

| Aluminum | ~276 | ~2.7 | ~102 |

| Fiberglass | ~440 | ~1.9 | ~231 |

Carbon fiber fabric is also different from regular cloth. Regular cloth uses natural or man-made fibers that are woven or knitted. Carbon fiber cloth uses fibers that are heated at high temperatures. This makes it much stronger and stiffer. The way the fabric is woven, like plain, twill, or satin, changes how strong and bendy it is. Carbon fiber composites use these fabrics with resins to make strong, light parts.

| Fabric Type | Structural Characteristics and Weaving Methods | Performance Advantages | Typical Applications |

|---|---|---|---|

| Woven Fabrics | Includes plain, twill, satin weaves; interlacing warp and weft fibers | High strength and stiffness; good draping and handling | Aerospace, automotive, sports goods |

| Knitted | Looped fiber structures | Flexible, good conformability | Specialized composite parts |

| Non-woven | Fibers bonded without weaving (e.g., spunlace, needle punching) | Lightweight, variable density | Reinforcement layers, insulation |

| Unidirectional | Fibers aligned in one direction | Maximum strength and stiffness along fiber direction | Sporting goods, aircraft main structures |

| Bidirectional | Balanced fiber orientation in two directions | Balanced strength and stiffness; good handling | Aerospace, wind energy, sports |

| Multi-axial | Fibers oriented in multiple directions | Multi-directional strength; optimized fiber weight | Wind turbine blades, large structural parts |

| NC2® (Upgraded NCF) | Seamless structure, even fiber distribution, improved resin flow | Enhanced mechanical properties, compression resistance | Automotive industry |

Note: Carbon fiber fabric is much stronger than regular cloth. It also lets people make parts that are both strong and light. This is very helpful for advanced industries.

Woven carbon fiber fabrics have fibers that cross each other. The fibers go over and under in different ways. There are three main weaves: plain, twill, and satin. Each weave makes the fabric feel and act differently. Plain weave looks like a checkerboard and is very stable. Twill weave has slanted lines and bends more easily. Satin weave is smooth and wraps around shapes well.

| Weave Type | Description | Structural Characteristics and Differences |

|---|---|---|

| Plain Weave | Fibers cross in a checkerboard pattern | High stability, less flexible, best for flat surfaces |

| Twill Weave | Fibers cross in diagonal lines (2x2, 4x4) | More flexible, forms complex shapes, moderate stability |

| Harness Satin Weave | Fibers pass over many, then under one | Most flexible, smooth surface, less stable |

Woven carbon fiber fabrics use different tow sizes like 3K, 6K, or 12K. "K" means thousands of filaments in a bundle. A 3K tow has 3,000 filaments and is strong and flexible. Bigger tows like 12K or 50K help make large parts faster but do not bend as well.

| Tow Size | Filaments (Thousands) | Typical Quality/Application | Performance & Use Case Impact |

|---|---|---|---|

| 3K | 3 | Aerospace-quality | High strength, good flexibility, best for complex shapes |

| 6K | 6 | Intermediate | Balanced cost and performance |

| 12K | 12 | Intermediate | Good for larger parts, less flexible |

| 50K | 50 | Automotive-quality | Lower cost, used in high-volume production |

Woven carbon fiber fabrics are used to make sheets, tubes, and shaped parts. They are tough and easy to work with. Many companies use them on the outside of products to stop damage. Some woven carbon fiber fabrics can resist fire and heat. These are good for safety clothes and building insulation.

Tip: Satin and twill weaves bend around curves better than plain weave. This is helpful for making parts with tricky shapes.

Unidirectional carbon fiber fabric has all fibers going the same way. It is not woven. This fabric is strongest along the fiber line. People can stack layers in different ways to make parts strong in more than one direction.

Unidirectional carbon fiber fabric is very strong for its weight.

It is stiff and does not bend much, but it is very strong in one direction.

This fabric is used in airplanes, cars, and sports gear.

Engineers use it for wind blades, bike frames, and fishing rods.

It is also used in medical tools and fixing buildings.

You can glue, wrap, or wind this fabric around things for support.

It does not rust and stands up to chemicals, so it lasts long.

Some unidirectional fabrics can resist fire for safety gear.

There are flexible types that fit special shapes.

| Characteristic / Application | Description |

|---|---|

| Fiber Orientation | All fibers run in one direction |

| Strength | Higher than steel, much lighter |

| Flexibility | Limited, but can be layered for custom shapes |

| Typical Uses | Wind turbine blades, sports shafts, bicycle frames, medical devices, building repair |

| Fire Resistance | Available in fire-retardant versions for safety gear |

Unidirectional carbon fiber fabric is often used with woven fabrics. This mix gives both strength and toughness. Unidirectional fabric gives main strength. Woven layers help stop cracks and add impact resistance.

Non-woven carbon fiber fabrics do not have fibers woven or knitted. The fibers are put down in random or layered ways and then stuck together. Some non-woven fabrics use recycled carbon fiber, which helps the environment.

Non-woven carbon fiber fabrics have many good points:

They are simple to make and cost less than woven types.

They can be made for special jobs, like stopping fire or separating oil and water.

Non-woven fabrics are light and can be used for things you throw away or keep.

Car, medical, and building companies use them for insulation, support, and filtering.

Note: Non-woven carbon fiber fabrics can be made to resist fire and bend easily. This makes them good for safety clothes, curtains, and building insulation.

But, non-woven carbon fiber fabrics are not as strong as woven or unidirectional ones. Their best features are being easy to use, quick to make, and using recycled fibers. This helps the planet and lets companies meet green goals.

| Aspect | Woven Carbon Fiber Fabrics | Unidirectional Carbon Fiber Fabric | Non-woven Carbon Fiber Fabrics |

|---|---|---|---|

| Fiber Orientation | Fibers woven in two directions (0/90, ±45) | All fibers aligned in one direction | Random or layered arrangement |

| Mechanical Properties | Good impact resistance, machinability | Highest strength and stiffness in fiber direction | Good fatigue resistance, easy to handle |

| Flexibility | Varies by weave (satin most flexible) | Limited, but can be layered | High, can fit many shapes |

| Typical Use | Sheets, tubes, molded parts | Wind blades, sports shafts, structural repair | Insulation, reinforcement, filtration |

| Fire-Retardant Options | Yes | Yes | Yes |

Fire-retardant and flexible carbon fiber fabrics are made in all three types. These fabrics protect from heat and flames and are still light and comfy.

Carbon fiber fabric has many good points for engineers and makers. It is very strong for how light it is. This material is five times stronger than steel. It is also only half as heavy as aluminum. Carbon fiber fabric is stiff and keeps its shape under heavy weight. It does not get tired or break easily, even with lots of use. The fabric does not rust or react with most chemicals. This helps it last longer in tough places. It can handle hot and cold without changing size. Carbon fiber fabric can carry electricity and heat. This makes it useful in electronics. Makers can shape it into many forms for different uses. Its smooth look makes products look new and cool.

Very strong for its weight

Stays stiff and keeps its shape

Does not wear out fast

Does not change size with heat or cold

Does not rust or react with chemicals

Carries electricity and heat

Can be shaped into many forms

Looks smooth and modern

Carbon fiber fabric also has some problems. It costs much more to make than steel or fiberglass. Making it needs special tools and skilled workers. Recycling is hard because the fibers are mixed with resins that do not melt. This makes throwing it away costly and slow. Recycling can also make the fibers weaker, so they are used for less important things. Not many places can recycle carbon fiber fabric. This means some industries cannot use it as much.

Costs a lot to make and recycle

Needs special tools to make

Hard and costly to recycle

Fibers get weaker after recycling

Not many places recycle it

Carbon fiber fabric is used in many fields because it is strong and useful. The table below shows where it is often used:

| Industry | Examples of Applications |

|---|---|

| Aerospace | Aircraft wings, fuselage sections, rudders |

| Automotive | Racing cars, electric vehicles, car body panels |

| Sports | Bicycles, tennis rackets, golf clubs, ski poles |

| Wind Energy | Turbine blades |

| Marine Engineering | Sailboats, yachts |

| Medical | Prosthetic limbs, orthopedic devices, imaging equipment |

| Construction | Reinforcement for load-bearing structures |

| Consumer Electronics | Laptops, smartphones |

| Fashion & Luxury | Designer accessories, watches, jewelry |

Note: Carbon fiber fabric helps these products stay light, strong, and dependable.

Many industries use carbon fiber fabric for new solutions. In aerospace, engineers put carbon fiber parts in planes like the X-59 jet. This makes planes lighter and faster to approve for flying. Small satellites also use carbon fiber fabric in their frames. This lowers costs and makes building them quicker.

The car industry has changed a lot. Carbon fiber fabric is not just for race cars now. Car makers use it in electric car batteries, body panels, and frames. This helps cars stay cooler, weigh less, and use less fuel. Companies like Tesla and BMW use carbon fiber to make cars safer and stronger.

Sports and fun products use carbon fiber fabric because it is strong and light. Golf clubs, skis, snowboards, and bike frames use this material. New uses include surfboards, Olympic boards, and racing tracks. Builders use carbon fiber fabric to fix buildings and make them last longer.

Note: Carbon fiber fabric helps make lots of parts or just a few. This lets people create custom pieces and test new ideas.

The future for carbon fiber fabric looks bright. Many industries want to use it more because it is light and strong. Planes and cars will keep using it, focusing on being green and working better. Builders will use it more as cities grow and want eco-friendly buildings.

Being green is very important now. New recycling ways, like using microwaves or chemicals, help keep fibers strong and cut down on trash. Recycled carbon fiber fabric is now used in cars and wind energy. Machines like 3D printers and robots make carbon fiber parts cheaper and cleaner. People now design things so they can be recycled later.

Big companies and governments help these changes with new rules and rewards. Because of this, the carbon fiber fabric market will grow fast, especially in North America, Europe, and Asia-Pacific. New smart materials and better recycling will change how carbon fiber is used next.

Carbon fiber fabric is known for being strong, light, and lasting a long time. Aerospace and car companies use it to make things safer and work better.

Patterned and twill weaves are liked because they are strong and look nice.

New ways to recycle and make carbon fiber fabric help the planet.

Better machines and AI help make carbon fiber fabric faster and cheaper.

As technology gets better, more companies will use these materials to help the world and make things greener.

Carbon fiber fabric has strong carbon filaments, not cotton or polyester. These fibers make the fabric very strong and light. Regular fabric is not as tough or long-lasting.

Yes, workers use sharp scissors or special tools to cut it. They can shape it to fit many things before adding resin. People should wear gloves and a mask to stay safe.

Carbon fiber fabric stands up to water, sunlight, and most chemicals. It does not rust or rot. Builders use it outside because it lasts a long time.

Engineers use carbon fiber fabric to make car parts lighter and stronger. They use it for body panels, hoods, and inside the car. This helps cars go faster and use less fuel.

Some companies recycle carbon fiber fabric using special methods. The recycled fibers are used for things like insulation or support panels. These products do not need the highest strength.